A personal fall arrest system is only as strong as the components that are used within the system. The process of selecting a suitable anchorage point for the system is essential for ensuring the safety of those who work at heights. Knowing this, it becomes critical to know what qualifies as a suitable anchorage point. The best way of ensuring worker safety while at heights is to test the fall arrest system and confirm its application.

Trivent Safety Consulting provides fall arrest system testing so that our clients will know and have the data to support the use of their fall arrest systems. With over 25 years of field experience, Trivent Safety Consulting can provide fall protection and rescue plans for any challenging scenario you may be faced with as well.

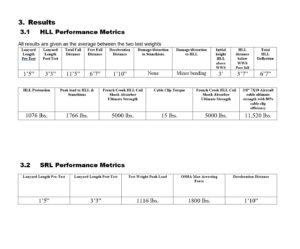

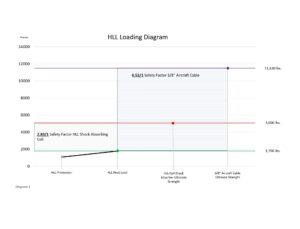

Customers will receive a detailed performance report and or video for their fall arrest systems. To be in compliance with OSHA 29 CFR 1926.502(d)(15) and (d)(15)(i)], companies using elevated horizontal lifelines need to know the forces applied to their system in the worst case scenario.

The OSHA standard states:

“Anchorages used for attachment of personal fall arrest equipment shall be . . . capable of supporting at least 5,000 pounds (22.2 kN) per employee attached, or shall be designed, installed, and used as follows: as part of a complete personal fall arrest system which maintains a safety factor of at least two.” [29 CFR 1926.502(d)(15) and (d)(15)(i)]

Examples of system testing include:

- Horizontal lifeline systems (HLL)

- Improvised anchorage systems (Beamers, Beam Straps, Cheater cable etc.)

- SRL & SRL-LE

- Cable grabs & rope grabbing systems.

- Fall arrest davits.

- Safety nets.