Earlier this year, in San Francisco there were two people charged with involuntary manslaughter in the death of an employee that was crushed while operating a forklift that he had not been formally trained or certified to operate. All powered industrial truck operators must be trained and certified in accordance with OSHA 1926.602 (d). Alfred Lee, owner of Good View Roofing and Building Supply Corp., and manager Alan Chan were charged with manslaughter in the death of employee Hua Quing Ruan. The accident occurred two years earlier in 2016 when the 60-year-old worker tipped over the forklift while attempting to load a bag of mortar mix while traveling down a loading dock ramp with a wooden pallet into a customer’s car. In transit the bag fell off the pallet and blocked the front wheel of the forklift. The worker then attempted to back away from the fallen mortar bag and backed off the side of the ramp and tipped the lift over. Surveillance video shows the employee trying to jump out of the way of the falling lift, however he was not able to get clear and was hit and crushed by the lift.

According to the Cal/OSHA investigators the employee was not wearing his seat belt and it played a significant factor in his death. In addition, the employee had no formal forklift training and was not certified to operate the lift. “When employers take workplace safety shortcuts, it’s employees that suffer,” District Attorney George Gascón said in a statement.

OSHA says, 70 percent of workplace accidents can be avoided with proper training and safety procedures. NIOSH states that the three most common types of injuries occur when: A forklift overturns; workers are struck, crushed, or pinned by a forklift; and workers fall from a forklift.

Tips on how to avoid accidents and near misses when operating a forklift:

- • Give your forklift a thorough inspection prior to use

• Only operate a forklift if you are authorized to do so

• Always use your seatbelt

• Become familiar with the features and functions of each forklift you operate - • Only pick up a load when you are sure it is stable

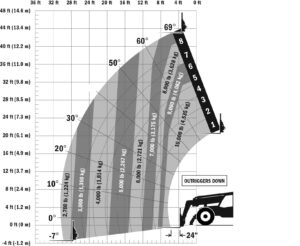

• Know and do not exceed the rated load capacity of your forklift

• Understand and know how to use your load capacity chart

NOT KNOWING THIS …

CAN LEAD TO THIS!

Requirements for Retraining and

Refresher training is required when:

• There has been an unsafe operation

• An accident or near miss

• An evaluation indicates that the operator is not capable of performing the assigned duties

• A new type of truck has been introduced into the workplace

• There has been three years since operators last evaluation

It is unfortunate events like this one that illustration the importance of getting your people the training they need to do the job as informed, safe workers. It has been said that the OSHA standards have been written in the blood of those that have come before us, before a standard was developed. Always be sure that workers who use heavy equipment have the experience and training needed to operate their machine safely. Lets protect our workers and the neighboring trades onsite from needless incidents and accidents that are preventable by receiving proper training!

NEED YOUR PEOPLE CERTIFIED?

No comment yet, add your voice below!