Construction safety loss prevention is the strategic integration of safety programs with asset protection to reduce theft, equipment damage, and financial losses on jobsites. In construction, loss prevention and safety are often treated as separate responsibilities. Typically, one is managed through security and inventory controls, while the other is handled through OSHA compliance and safety training. However, in reality, construction safety loss prevention demonstrates that these functions are deeply interconnected on jobsites across the United States.

Construction safety loss prevention is the strategic integration of safety programs with asset protection to reduce theft, equipment damage, and financial losses on jobsites. In construction, loss prevention and safety are often treated as separate responsibilities. Typically, one is managed through security and inventory controls, while the other is handled through OSHA compliance and safety training. However, in reality, construction safety loss prevention demonstrates that these functions are deeply interconnected on jobsites across the United States.

Unsafe jobsites don’t just lead to injuries—they also lead to theft, equipment damage, project delays, and costly insurance claims. In fact, according to the National Equipment Register, construction equipment theft costs the industry over $1 billion annually. Moreover, only 23% of stolen equipment is ever recovered.

Consequently, the most effective construction safety loss prevention strategies begin with a strong, well-executed safety program that protects both workers and assets.

Understanding Construction Safety Loss Prevention

From commercial and industrial projects to infrastructure and energy work, construction jobsites nationwide share the same risks. Specifically, these include heavy equipment, high-value materials, rotating crews, and demanding schedules. Therefore, construction safety loss prevention addresses these interconnected challenges.

Furthermore, when safety controls break down, losses increase through multiple channels:

- Equipment damage and misuse – For instance, the Equipment Leasing and Finance Association reports that improper equipment use accounts for 30% of all equipment-related losses

- Material theft and vandalism – Similarly, FBI crime statistics show construction sites are 400% more likely to experience theft than other business locations

- Unauthorized jobsite access – Which subsequently creates both safety hazards and security vulnerabilities

- Project delays and downtime – Costing an average of $1,600 per hour according to Construction Dive

- Workers’ compensation and general liability claims – Additionally, NCCI research indicates construction has one of the highest workers’ comp claim frequencies

As a result, a jobsite with weak safety oversight often lacks structure and accountability—two essential elements of effective construction safety loss prevention.

The Hidden Costs of Weak Safety Oversight

When safety oversight is inconsistent, it creates gaps that affect far more than injury risk. In other words, the consequences extend well beyond worker safety into financial performance. This is why construction safety loss prevention must address both human and asset protection.

Structure Creates Prevention in Construction Safety Loss Prevention

First and foremost, structure on a jobsite means: – Clear expectations and defined responsibilities – Documented safety procedures – Controlled access points – Organized material staging – Routine inspections – Clear equipment-use protocols

Without structure, jobsites become reactive. As a result, tools are left unsecured, materials are staged wherever space allows, and equipment use goes untracked. Ultimately, these conditions increase both safety incidents and asset loss—undermining construction safety loss prevention efforts.

Accountability Ensures Compliance

In addition to structure, accountability ensures those systems are followed. Specifically, when safety expectations are enforced consistently, crews are more likely to:

- Secure tools at end of shift

- Report damaged or missing equipment immediately

- Challenge unauthorized access

- Take ownership of their work areas

Furthermore, research from the Construction Industry Institute shows that projects with strong accountability systems experience 40% fewer safety incidents and 35% less equipment loss—demonstrating the power of construction safety loss prevention.

The “Nobody’s Watching” Effect

On the other hand, weak safety oversight sends a clear message: no one is watching. Consequently, on construction sites, that perception quickly leads to:

- Increased theft and equipment misuse

- Poor housekeeping practices

- Delayed incident reporting

- Higher claim frequency

- High-risk behavior normalization

In contrast, strong safety oversight corrects this by creating visibility and presence. Therefore, regular safety walks, documented inspections, and consistent follow-through reinforce order and responsibility—deterring loss while protecting workers through comprehensive construction safety loss prevention.

Safety oversight creates order. And where there is order, there is less loss.

Building a Safety Culture for Construction Safety Loss Prevention

A strong safety culture protects more than people—it also protects assets through effective construction safety loss prevention. Indeed, according to CPWR – The Center for Construction Research and Training, companies with mature safety cultures report 70% fewer lost-time injuries and significantly lower equipment loss rates.

Moreover, on jobsites where workers are trained, engaged, and accountable, crews are more likely to:

- Secure tools and materials before leaving work areas

- Report damaged or missing equipment within the same shift

- Respect controlled access points and challenge unfamiliar personnel

- Maintain clean, organized work areas that reduce hazards and improve visibility

Ultimately, when crews take ownership of safety, they take ownership of the jobsite itself—creating a foundation for successful construction safety loss prevention.

Inventory Management: Where Construction Safety Loss Prevention Meets Operations

Poor inventory management is one of the most overlooked contributors to both injuries and financial loss. Nevertheless, it represents a critical intersection point in construction safety loss prevention.

Specifically, untracked tools and poorly staged materials frequently result in:

- Trip and struck-by hazards (OSHA’s leading cause of construction fatalities)

- Equipment damage from improper storage

- Lost or stolen materials

- Reduced productivity and project delays

On the other hand, effective inventory management supports construction safety loss prevention by:

- Assigning accountability for tools and equipment

- Reducing clutter and unnecessary movement

- Improving material visibility

- Preventing unauthorized use

- Creating audit trails for loss investigation

In fact, the Associated General Contractors of America estimates that improved inventory practices can reduce material waste and loss by up to 25%—a significant benefit of integrated construction safety loss prevention.

7 Construction Safety Loss Prevention Strategies

The following construction safety loss prevention strategies improve safety while directly reducing loss. Additionally, each strategy builds upon the others to create comprehensive protection.

1. Control Jobsite Access for Construction Safety Loss Prevention

First, unauthorized access is a safety hazard first and a theft risk second. Therefore, implement: – Perimeter fencing with controlled entry points – Badge or check-in systems for all personnel – Clear signage identifying restricted areas – Visitor escort protocols

These access controls are fundamental to construction safety loss prevention.

2. Improve Lighting and Visibility

Second, well-lit jobsites reduce slips, trips, and falls while simultaneously discouraging theft and vandalism during low-visibility conditions. Furthermore, NIOSH research shows proper lighting reduces incident rates by up to 30%—supporting both safety and construction safety loss prevention goals.

3. Standardize Material Staging

Third, designated staging areas provide multiple benefits for construction safety loss prevention. Specifically, they: – Reduce struck-by incidents – Minimize equipment damage – Prevent material loss – Improve workflow efficiency

4. Maintain Strong Housekeeping Standards

Fourth, good housekeeping supports OSHA compliance and makes missing tools or materials immediately noticeable. Additionally, the “5S” methodology (Sort, Set in Order, Shine, Standardize, Sustain) is highly effective for construction safety loss prevention on construction sites.

5. Integrate Construction Safety Loss Prevention Into Safety Meetings

Fifth, daily toolbox talks should include construction safety loss prevention discussions on: – Tool control and accountability – Equipment inspections and proper use – Site security observations – Material tracking – Not just injury prevention

6. Implement Equipment Tracking Technology

Sixth, modern construction safety loss prevention solutions include: – GPS tracking for heavy equipment – RFID tags for tools and materials – Mobile inventory apps – Telematics for usage monitoring

7. Conduct Regular Safety and Security Audits

Finally, combined safety-security audits identify vulnerabilities before they result in loss. As a result, proactive identification prevents costly incidents and strengthens construction safety loss prevention programs.

Leadership’s Role in Construction Safety Loss Prevention

Supervisors and safety leaders are the frontline defense against loss. In fact, according to the Construction Management Association of America, leadership engagement is the single most important factor in jobsite safety performance and effective construction safety loss prevention.

Effective leaders consistently:

- Conduct regular safety and security walks

- Address unsafe behaviors immediately

- Track equipment use and storage patterns

- Hold crews accountable consistently

- Model expected behaviors

- Investigate incidents thoroughly

Therefore, strong leadership ensures safety expectations and construction safety loss prevention practices are consistently followed.

Incidents, Near Misses, and Hidden Financial Loss

Incident investigations should not focus solely on injuries. Instead, they often reveal construction safety loss prevention opportunities through:

- Equipment misuse patterns

- Poor storage practices

- Training gaps

- Security vulnerabilities

- Process weaknesses

Near misses are early warning signs—not just of potential injuries, but also of future losses. Moreover, the Heinrich pyramid suggests that for every serious injury, there are 29 minor injuries, 300 near misses, and thousands of unsafe acts.

Consequently, addressing near misses protects both workers and project assets through proactive construction safety loss prevention.

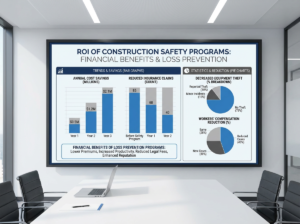

The ROI of Construction Safety Loss Prevention

Across construction projects throughout the United States, construction safety loss prevention programs share the same goal: risk reduction. Furthermore, the financial benefits are substantial and measurable.

Strong construction safety loss prevention programs lead to:

- Fewer injuries – Reducing workers’ comp costs by 20-40% (Liberty Mutual Research)

- Reduced equipment theft and damage – Saving $50,000-$500,000 per major project

- Lower insurance premiums – EMR reductions can save 15-30% on premiums

- Less downtime – Preventing costly project delays

- Improved project performance – Better schedule adherence and profitability

In addition, according to OSHA’s Safety Pays calculator, every dollar invested in workplace safety returns $4-$6 in cost savings—demonstrating the powerful ROI of construction safety loss prevention.

Construction safety loss prevention does not start with locks or cameras—instead, it starts with planning, training, and accountability.

And it starts with a hard hat.

Final Thoughts: Construction Safety Loss Prevention Is the Foundation

Construction safety loss prevention on jobsites doesn’t start with cameras, fences, or inventory spreadsheets. Rather, it starts with how the jobsite is run every day.

Throughout this discussion, one theme remains consistent:

✓ Strong safety oversight creates structure

✓ Accountability reduces theft, damage, and misuse

✓ Inventory management supports both safety and cost control

✓ Leadership presence and safety culture deter loss before it occurs

In short, protecting people and protecting assets through construction safety loss prevention are not competing priorities—they are the same priority.

If your organization is experiencing tool loss, equipment damage, frequent incidents, or rising insurance costs, the solution may not be more security. Instead, it may be better safety systems, stronger oversight, and clearer accountability through comprehensive construction safety loss prevention.

Take the Next Step With Trivent Safety Consulting

Whether you’re managing a single project or multiple jobsites nationwide, now is the time to evaluate how well your safety program supports construction safety loss prevention. Furthermore, a focused review of safety oversight, inventory practices, and leadership engagement can uncover risks before they turn into costly losses.

Trivent Safety Consulting offers construction safety loss prevention services including: – Comprehensive safety program audits – Customized loss prevention strategies – OSHA compliance training – Mock safety inspections – Temporary safety staffing solutions – Bilingual training programs

With over 75 years of combined field experience, our team understands the real-world challenges of balancing productivity, safety, and construction safety loss prevention.

Ready to strengthen your construction safety loss prevention program, reduce loss, and protect your bottom line?

Contact Trivent Safety Consulting today and start building a safer, more secure jobsite—one hard hat at a time.