Are you ready to elevate your rigging capabilities and become a master of the trade? Look no further, because we have just the course for you!

Introducing the Trivent Master Rigger Course – an exhilarating opportunity that will take your rigging skills to unprecedented heights. Whether you’re a seasoned professional or just starting out in the industry, this comprehensive training program is designed to push boundaries, expand knowledge, and transform even the most proficient rigger into an unstoppable force. Get ready to embark on a thrilling journey as we dive deep into advanced techniques, cutting-edge equipment, and unparalleled expertise. Buckle up and get ready – it’s time to level up your rigging game!

Introduction to the Trivent Master Rigger Course

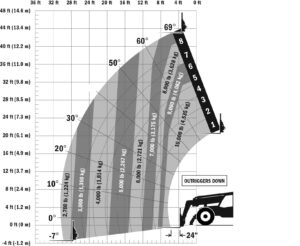

The Trivent Master Rigger Course is an intensive, hands-on training program that covers all aspects of professional rigging. The course is designed for riggers who want to take their skills to the next level and become certified master riggers. The course includes classroom instruction and practical training on a variety of topics, including calculating sling tension, Load Weight Estimation, coefficients of friction and determining the center of gravity for asymmetrical loads. Students will also learn about the latest rigging equipment and how to use it properly. Upon completion of the course, students will be able to safely and efficiently rig for a variety of applications. Whether you’re looking to start your own rigging business or simply want to improve your rigging skills for your current job, the Trivent Master Rigger Course is the perfect choice.

What is Rigging?

Rigging is the process of planning, selecting, and using complex slinging techniques to move material using cranes or hoists. It is a highly skilled trade that requires training and certification. Riggers are responsible for the safety of the workers and equipment they are using, as well as the load they are lifting. Rigging involves attaching loads to cranes or other lifting devices using various types of hardware, such as chains, ropes, pulleys, and blocks. A rigger must be able to calculate the weight of the load and the size and capacity of the crane or other lifting device being used. They must also know how to secure the load so that it does not displace while it is being lifted. Riggers must also be familiar with OSHA regulations and standards pertaining to rigging operations. They must be able to properly inspect all rigging equipment before each use and keep accurate records of all inspections.

Rigging is the process of planning, selecting, and using complex slinging techniques to move material using cranes or hoists. It is a highly skilled trade that requires training and certification. Riggers are responsible for the safety of the workers and equipment they are using, as well as the load they are lifting. Rigging involves attaching loads to cranes or other lifting devices using various types of hardware, such as chains, ropes, pulleys, and blocks. A rigger must be able to calculate the weight of the load and the size and capacity of the crane or other lifting device being used. They must also know how to secure the load so that it does not displace while it is being lifted. Riggers must also be familiar with OSHA regulations and standards pertaining to rigging operations. They must be able to properly inspect all rigging equipment before each use and keep accurate records of all inspections.

Benefits of Taking the Trivent Master Rigger Course

The Trivent Master Rigger Course is designed to take your rigging skills to the next level. This course will provide you with the knowledge and skills necessary to become a master rigger. You will learn how to safely and effectively rig loads for lifting, lowering, and moving them into position. In addition, you will learn how to inspect and maintain rigging equipment.

Upon completion of the Trivent Master Rigger Course, you will be able to:

- Safely and effectively rig loads for lifting, lowering, and moving them into position

- Inspect and maintain rigging equipment

- Understand the principles of load analysis and mechanical advantage

- Select appropriate rigging methods and techniques for specific tasks

- Calculate sling tensions and center of gravity locations

- Plan lift sequences

Topics Covered in the Course

This course covers a variety of topics that are essential for riggers who want to take their skills to the next level.

These topics include:

These topics include:

- Sling Types

- Sling Capacities

- Sling Inspections

- Hardware inspections

- Hardware Capacities

- Hitch Types

- Load Control

- Power Line Safety

- Crane / Hoist Dynamics

- Calculating Sling tensions

- Load Weight Estimation

- Block & Fairlead Loading Calculations

- Coefficients of Friction Calculations

- Load Factors & Weight Distribution Calculations

- Practical (Hands On) Applications for:

- Sling Tension Calculations

- Load Weight Estimation

By the end of the course, students will have a thorough understanding of these topics and will be able to apply them in real-world situations.

Prerequisites for Taking the Course

In order to take the Trivent Master Rigger Course, you must first take the Trivent Qualified Rigger & Signalperson training course.

Facilities and Instructors at Trivent

The Trivent Master Rigger Course is held at the Trivent training center in Wheatridge, Colorado. The course is taught by experienced riggers who have a wealth of knowledge and experience in the industry. Attendees will get a unique hands-on experience using the indoor Trivent training tower to test principals learned in the classroom in a controlled hands-on learning environment. The facility is equipped with all the necessary rigging equipment and supplies, and the instructors are knowledgeable and experienced in all aspects of rigging. The course is designed to give students a comprehensive understanding of rigging, from the basics to advanced techniques. Students will learn how to safely and effectively rig various types of equipment, including trusses, motors, pulleys, and winches. They will also learn about different types of rigging hardware and how to select the right type of hardware for each application.

Tips for Making the Most of the Course

If you’re looking to take your rigging skills to the next level, the Trivent Master Rigger Course is the perfect way to do it. Here are some tips for making the most of the course:

- Pay attention to the lectures and demonstrations.

This is a hands-on course, but there will also be plenty of opportunities to learn from the instructors. Make sure you take advantage of those moments. - Practice, practice, practice.

The more you can get your hands on the equipment and put what you’re learning into action, the better. - Ask questions.

No matter how much experience you have, there’s always more to learn. Don’t be afraid to raise your hand and ask questions when you’re unsure about something. - Get feedback from the instructors.

Throughout the course, you’ll have plenty of chances to get feedback from the instructors on your progress. Use that feedback to help improve your skills. - Stay focused and dedicated.

This is a challenging course, but if you stay focused and dedicated, you’ll come out of it a better rigger than when you started.

Conclusion

Learning to rig is an important step in taking your career to the next level. The Trivent Master Rigger Course offers a comprehensive and engaging training program for beginners and experienced riggers alike, providing the knowledge needed to stay safe while expanding rigging skills. With this course, you will be well-equipped with the tools necessary to make heavy things resist gravity!

Learning to rig is an important step in taking your career to the next level. The Trivent Master Rigger Course offers a comprehensive and engaging training program for beginners and experienced riggers alike, providing the knowledge needed to stay safe while expanding rigging skills. With this course, you will be well-equipped with the tools necessary to make heavy things resist gravity!

Blog Author: Bryan McClure