Introduction to Confined Space Training

Confined spaces present unique challenges and hazards that can turn routine tasks into life-threatening situations. Whether it’s a storage tank, a tunnel, or a manhole, working in these environments requires specialized training to ensure safety. The stakes are high—one misstep can have serious consequences. That’s where proper confined space training comes into play.

Confined spaces present unique challenges and hazards that can turn routine tasks into life-threatening situations. Whether it’s a storage tank, a tunnel, or a manhole, working in these environments requires specialized training to ensure safety. The stakes are high—one misstep can have serious consequences. That’s where proper confined space training comes into play.

At the forefront of this essential training is Trivent Safety Consulting. Renowned for their expertise and commitment to excellence, Trivent is setting new standards in confined space safety education. Dive deeper with us as we explore what makes their approach not just effective but transformative for organizations navigating the complexities of 29 CFR 1926 Subpart AA regulations and beyond.

The Importance of Proper Confined Space Training

Confined spaces present unique hazards that require specialized knowledge and skills. Workers in these environments face risks like toxic gases, limited oxygen, and potential structural collapses. Proper training is essential for their safety.

Understanding the specific dangers associated with confined space entry can make a significant difference. Awareness of emergency procedures is crucial when every second counts.

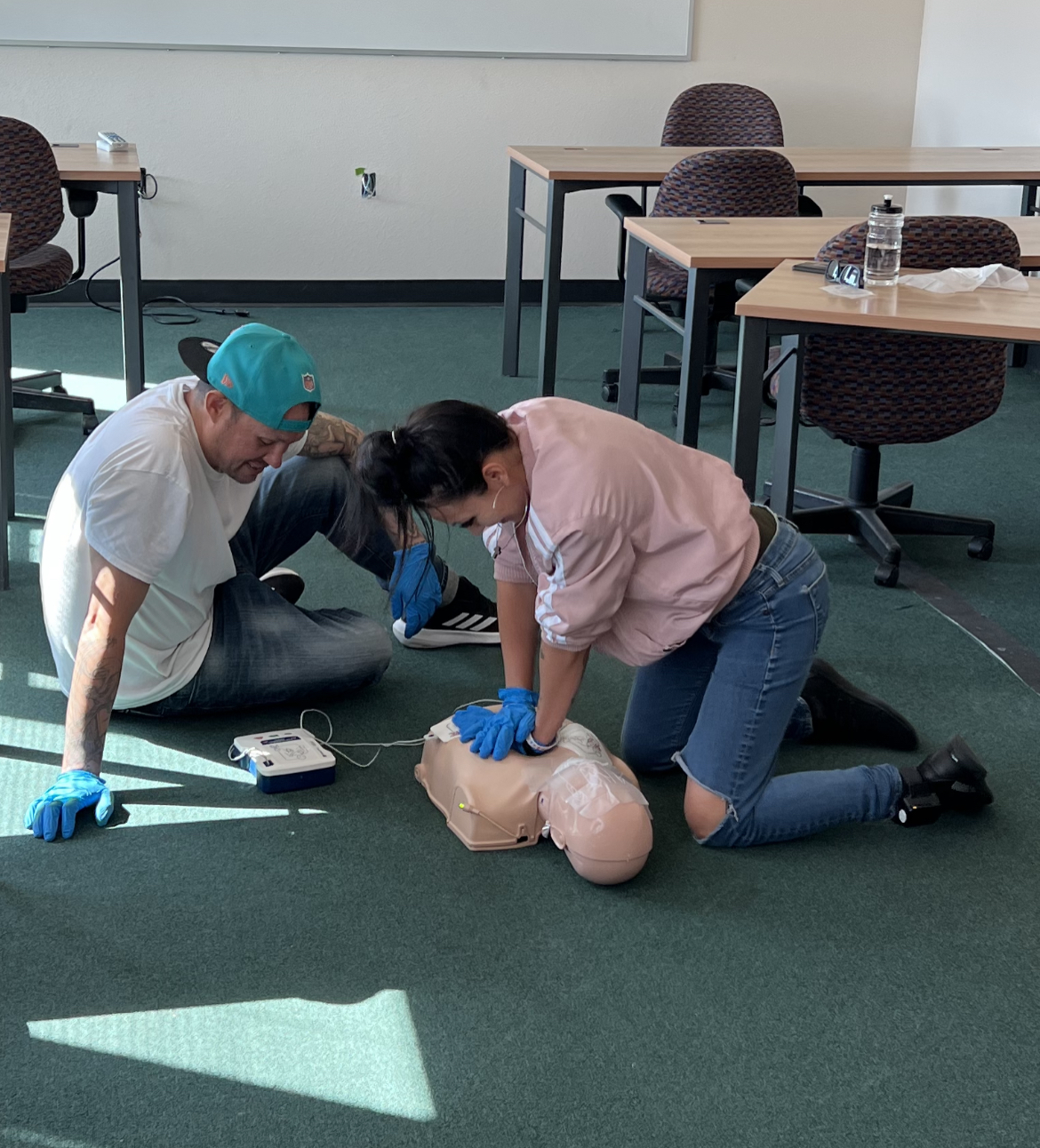

The importance of practical, hands-on experience cannot be overstated. It prepares workers to respond effectively under pressure, ensuring they know how to act swiftly if things go wrong.

Moreover, compliance with regulations such as 29 CFR 1926 Subpart AA is non-negotiable in today’s workplace environment. Employers must not only meet legal standards but also prioritize employee well-being through effective training programs.

Investing in proper confined space training fosters a culture of safety that benefits everyone involved—workers return home safely each day while companies minimize costly incidents and downtime. Are you looking to enhance workplace safety and compliance? Trivent Safety Consulting OSHA 10 and OSHA 30 courses equip employees with the necessary knowledge and skills to be safe.

What Sets Trivent Safety Consulting Apart?

Trivent Safety Consulting stands out in the crowded field of confined space training due to its unwavering commitment to quality and safety.

Their programs are not just theoretical; they provide participants with hands-on experience that is crucial for real-world applications. This practical approach ensures that learners leave with skills they can immediately apply on the job.

What truly distinguishes Trivent is their deep understanding of 29 CFR 1926 Subpart AA regulations. They tailor their training to meet and exceed compliance requirements, ensuring clients are well-prepared for inspections and audits.

The safety team at Trivent comprises seasoned professionals who have firsthand experience in various industries. Their insights enrich the learning environment, making it engaging and relevant.

Additionally, Trivent emphasizes a culture of safety within organizations, helping teams foster an environment where safety protocols become second nature rather than an afterthought.

Trivent’s Unique Approach to Confined Space Training

Trivent Safety Consulting revolutionizes confined space training with a hands-on approach. Instead of traditional lectures, participants engage in real-world scenarios that mimic actual working conditions. This method fosters deeper understanding and retention.

Each session is tailored to the specific needs of the industry and workplace environments. By integrating practical exercises, Trivent ensures that trainees not only learn regulations but also apply them effectively.

Instructors are seasoned professionals who bring years of field experience to the table. They share insights from their own safety challenges, providing valuable lessons that textbooks simply cannot offer.

The focus on interactive learning creates an environment where questions are encouraged. Attendees feel empowered to voice concerns or uncertainties about confined space operations, leading to greater overall safety awareness.

This unique strategy transforms compliance with 29 CFR 1926 Subpart AA into actionable skills and knowledge for every worker involved in confined space activities.

Success Stories from Trivent’s Clients

Trivent Safety Consulting has transformed the safety culture of numerous organizations through its tailored confined space training programs. One notable client, a manufacturing facility, faced significant risks due to outdated practices. After partnering with Trivent, they reported a remarkable 50% reduction in near-miss incidents.

Another success story comes from a construction company that was struggling to meet compliance requirements under 29 CFR 1926 Subpart AA. Through hands-on experience provided by Trivent’s expert trainers, their team gained confidence and improved knowledge significantly. They are now fully compliant and have enhanced their overall safety protocols.

Clients often praise Trivent for delivering practical solutions that resonate on-site. The real-world scenarios used during training sessions allow employees to apply what they’ve learned immediately, leading to better retention and safer work environments. Such impactful outcomes highlight why so many choose Trivent as their trusted partner in confined space safety initiatives.

Benefits of Choosing Trivent for Confined Space Training

Selecting Trivent Safety Consulting for confined space training brings numerous advantages that enhance workplace safety and compliance. First, Trivent emphasizes hands-on experience, ensuring participants engage in practical scenarios tailored to real-world situations.

Trivent’s trainers are industry experts who possess extensive knowledge of 29 CFR 1926 Subpart AA regulations. Their insights bridge the gap between theory and application, empowering teams with essential skills.

Additionally, Trivent customizes training programs to fit specific organizational needs. This personalized approach fosters a deeper understanding of confined space safety protocols relevant to different industries.

Furthermore, clients report improved employee confidence when entering confined spaces after completing their courses. Such assurance translates into safer practices on-site and minimizes risks associated with confined environments.

By fostering an interactive learning environment, Trivent also encourages open discussions about safety challenges. This collaborative atmosphere cultivates teamwork and strengthens overall safety culture within organizations.

Summary

Elevate Your Safety Standards with Trivent

When it comes to confined space training, the stakes are high. The potential risks associated with working in confined spaces require thorough knowledge and practical skills. Trivent Safety Consulting understands this need and has tailored its programs to ensure that every participant walks away equipped for real-world scenarios.

By focusing on hands-on experience as outlined in 29 CFR 1926 Subpart AA, Trivent not only meets but exceeds industry standards. Their unique approach combines theoretical learning with practical drills, ensuring that learners can apply their knowledge effectively in the field.

Countless success stories from satisfied clients highlight the transformative impact of Trivent’s training programs. Organizations have reported significant improvements in safety culture and a noticeable reduction in incidents after implementing what they’ve learned through Trivent.

Choosing Trivent means investing in quality education designed specifically for confined space safety. With a commitment to excellence and a proven track record, you can elevate your organization’s safety standards significantly.

Make the wise choice today—partner with Trivent Safety Consulting for unparalleled expertise and support in confined space training.

- Call or sign up today! 800-819-6092 or click here.