No matter where you are, or where you are heading, you may have experienced our topic of discussion today and that is distracted driving. We’ve all seen it play out before, from the person sitting at the front of the traffic light who needs to be alerted from someone behind as they sit comfortably at the intersections pole position, to the more serious infraction of not being able to stay in one driving lane. One thing is for sure and that as technology continues to evolve so does the frequency of distracted driving issues. It would be nice to have all distracted driving issues come to end after taking a moment to address and discuss this ongoing epidemic, but the reality is there will be a high likelihood of this continuing to be an issue for the foreseeable future. So lets take a moment today and discuss one of the main distractions we see on a daily basis while driving…. Texting!

Texting is the Most Dangerous Type of Distracted Driving

According to the CDC there are 3 types of driving distractions:

- Visual: a distraction that diverts your eyes from the road

- Manual: something that causes you to take your hands off the wheel

- Cognitive: anything that takes your mental focus off the road

The National Highway Traffic Safety Administration has determined that texting while driving is the most dangerous type of distracted driving. This is mostly because texting combines all 3 types of driving distractions at once: visual, manual and cognitive.

Pictured above is the fatal aftermath of a distracted driving incident in California, the driver was sentenced to a year in jail after the crash that killed two people. Scenes like the above are a grizzly reminder of what can potentially happen if we become complacent and allow ourselves to become distracted behind the wheel of an automobile.

According to a Cambridge Mobile Telematics survey, most drivers are more afraid of distracted drivers than drunk drivers, but curbing the problem isn’t easy.

Distracted driving has become an epidemic, but do people believe that it is even more dangerous than drunk driving? According to our recent survey of more than 700 drivers, the answer is yes; 63 percent of respondents noted they are more afraid of distracted drivers than drunk drivers.

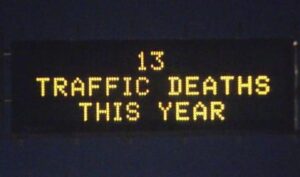

Each day, roughly 9 people are killed in crashes caused by distracted drivers – equating to about 3,285 deaths a year. When compared to the number of people killed in drunk driving-related crashes in 2016 (10,497) that number is smaller, driving while distracted is actually more dangerous. Texting and driving at 55 miles per hour is the equivalent of driving the length of a football field with eyes closed. Even more, it takes the average sober driver .54 seconds to hit the brake. For a driver who’s been drinking, add four feet to their reaction time, but add 70 feet for someone who has been texting. Wanna read more? Click the link: www.cmtelematics.com/blog/distracted-driving-vs-drunk-driving-fear-solutions/

At the end of the day nobody wants to become part of a statistic, Trivent Safety Consulting understands the risks and inherit dangers of every day driving and has developed a defensive driving course to help bring awareness and discussion to the forefront of what most us take for granted on a daily basis. Interested in learning more? Contact us today so we can heighten awareness and provide valuable training to your team. We can help inform and build a safety culture for you and your work force!

By: Scott Seppers