Perhaps one of the most impressive eye-catching pieces of equipment you will find on a construction site is a crane. These titans of the industry come in a variety of types and configurations, tower cranes, conventional crawler, rough terrain and truck mount are some the most common in use today. For the average person traveling down the road these pieces of equipment are the main identifier that reveals that there is construction under way. They also can be a physical indicator of how well an economy is doing, Denver recently was ranked third in the nation for having the most crane booms erected in the air. With this much activity and construction it is vital to ensure the safety of the workers along with the safety of the public. OSHA has measures and standards in place that require the inspection and documentation of cranes to insure they are in good safe working condition. Let’s take a look at and review three types of crane inspections. These are Frequent inspections, Periodic inspections, and Annual Inspections.

How often should a crane be inspected?

To begin a Frequent inspection must be performed by the operator who is knowledgeable in the  operations of the equipment that he or she is working with. Frequent inspections are often referred as daily or shift inspections. Although not required, it is recommended to record the inspection in the equipment logbook. A crane that has not been used for more than a month, but less than six months requires all frequent inspections before being used. Items of inspection should include:

operations of the equipment that he or she is working with. Frequent inspections are often referred as daily or shift inspections. Although not required, it is recommended to record the inspection in the equipment logbook. A crane that has not been used for more than a month, but less than six months requires all frequent inspections before being used. Items of inspection should include:

• Operational Controls

• Drives

• Air & Hydraulic Pressure Lines

• Hooks & Latches

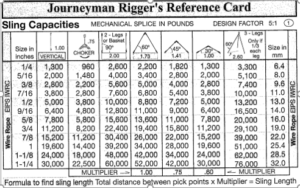

• Wire Rope

• Tires (If Equipped)

• Ground Conditions

• Safety Devices

Periodic inspections or often referred as Monthly inspections are the next category of inspection, these are required to be performed by a competent person. The periodic inspection procedure is intended to determine the need for repair or replacement of parts. All cranes are designed and manufactured with a safety factor in place, but all machines begin to depreciate over time and repetitive use, The Periodic inspections are designed to identify and address these situations. They are similar to Frequent inspections but require a written record to be documented and maintained by the crane’s user/owner. The inspection and information must contain the name, date and signature of the person who performed the inspection.

One of the standards that are in place to ensure crane safety is the annual inspection, Annual comprehensive inspections are required to be performed at 12-month intervals by a qualified person. OSHA requires that all active cranes must be inspected once a year at the minimum by a qualified person. However, depending on the crane’s usage, additional inspections will be required. Annual inspections are a vital component in ensuring the crane is in good working condition and safe for overhead lifts. These inspections are the most thorough of the three and provide a comprehensive look at the following:

- Control mechanism operations

- Control and drive mechanisms free of excessive wear or damage

- Hooks and latches are free of deformation, cracks, excessive wear’ or damage

- Wire Rope reeving complies with the manufacturer’s specifications

- Wire rope condition and free from damage

- Sheaves and drums do not have cracks or significant damage

- Safety Devices- Crane level indicator, Anti-two block system, jib stops, boom stops, etc.

- Equipment structure

- Boom integrity Hydraulic or lattice

- Hydraulic and Pneumatic Pumps & Motors

- Tires (If Equipped)

- Ground Conditions

At the end of the day following the inspection process and procedures for cranes is a critical component for ensuring worker and public safety at and around construction sites, as well as following the manufactures recommended maintenance program. Our crane inspection experts travel across the United States ensuring our clients equipment is safe for overhead lifts, and both have over 25 years’ experience. If you would like more information, the Colorado Crane Experts at Trivent Safety Consulting are available to help with any crane or rigging challenges that you may face at your project.

At the end of the day following the inspection process and procedures for cranes is a critical component for ensuring worker and public safety at and around construction sites, as well as following the manufactures recommended maintenance program. Our crane inspection experts travel across the United States ensuring our clients equipment is safe for overhead lifts, and both have over 25 years’ experience. If you would like more information, the Colorado Crane Experts at Trivent Safety Consulting are available to help with any crane or rigging challenges that you may face at your project.