Have you ever wondered what might happen if OSHA was to stop by on a project your working on, more importantly have you ever had a moment that caused you to pause and ask yourself if the task you were involved with was being performed as safely as possible? If you’re like me, than the answer is a resounding yes, but the unknown of what might be discovered on such an inspection can be paralyzing. It is for reasons like this many people take an out of site out of mind approach and for better lack of term bury their heads in the sand and ignore where there might be safety issues. Unfortunately though ignoring a potential problem doesn’t make it go away, but can often lead to unintended consequences such as general acceptance to a potential hazard that has been left by the way side. OSHA states ” If your employer is covered by the Occupational Safety and Health Act, you have the right to request an OSHA inspection. OSHA also may make requested inspections. Inspections can cover the entire workplace or just a few operations. OSHA calls its inspectors “compliance officers.”

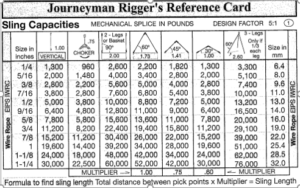

As mentioned earlier with so many topics and items that are up for review it can be a little overwhelming when thinking about compliance to the standards and how far they range. Some examples to think about are, qualified riggers and signal people, anyone involved with rigging or signaling overhead loads with cranes is required to have qualified rigger and signal person training. Scaffolds, who is the competent person who is over seeing the construction and maintenance of scaffolding on the project? Is the scaffold being inspected and signed off ready for use each day? Is the forklift operator certified to run the equipment? Employees working at heights, have they received fall protection training? These are just a few examples that can be up for review on an inspection, not to mention the administrative portion that can be conducted before the site walk inspection begins.

“Trivent Safety Consulting wants to help you start the new year and project as safe as possible.”

So how can we be prepared and know that are projects are in compliance and assigned tasks are being performed as safely as possible? Frequent site inspections that refer to the OSHA compliance standards on any and all topics that are applicable to the project your working on. Site inspections are a great tool to use on construction sites. They can develop a picture for you on how things are looking safety wise on the project and can also reveal areas for improvement where training is needed. You may be asking yourself “how can I conduct frequent site inspections based on the OSHA compliance standards if I don’t know all of them?”

Trivent Safety Consulting wants to help you start the new year and project as safe as possible. We are offering one free site inspection per company from now till the end of January. This inspection is OSHA based and will hit all topics of construction and compliance that are applicable to your project. Any recognized deficiency’s will come with a picture of that deficiency and why it is in violation of the standard. If a lack of training or policy is discovered one of our professionals can help you address and correct the situation in a timely manner. We also offer onsite safety representation to help you work through and establish a safer work site. All reports are 100% confidential to the requesting company. Contact us today and take advantage of this free no obligation inspection and see what we can do for you in the future to provide a safe and informed work force on the job site!

Author: Scott Seppers